The use of EPP and EPS is increasing, thanks to the extraordinary properties of this material: strength, lightness and sustainability.

More and more sectors are introducing it: food and non-food packaging, construction, automotive, sports equipment ... and more and more attention is being paid to its aesthetic performance.

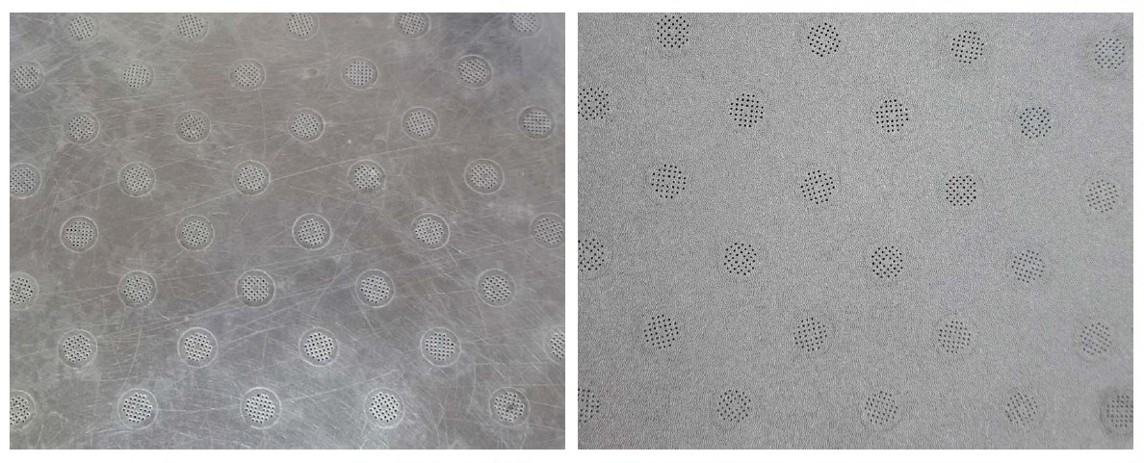

The typical pop corn effect that characterizes this material can be transformed thanks to aesthetic textures to give a precise identity to the objects.

In our digital catalogue we have numerous industrialized textures for EPP and EPS molding. We also create custom textures starting from your request or we replicate finishes already present on your molds and samples.

From grains to vermicelli, to more elaborate finishes (geometric or artistic): aesthetic textures can transform the appearance of your product.

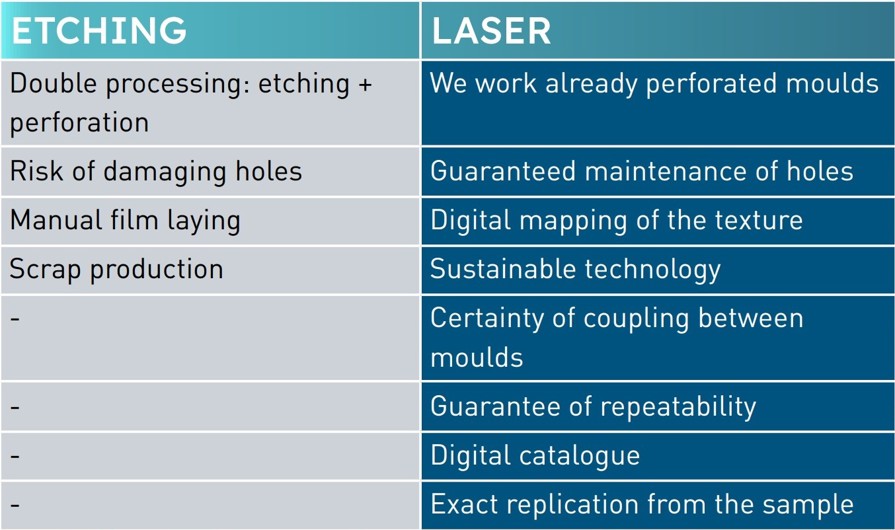

Customizing surfaces with the laser is simple, fast and safe: the laser cuts the aluminium moulds very well.

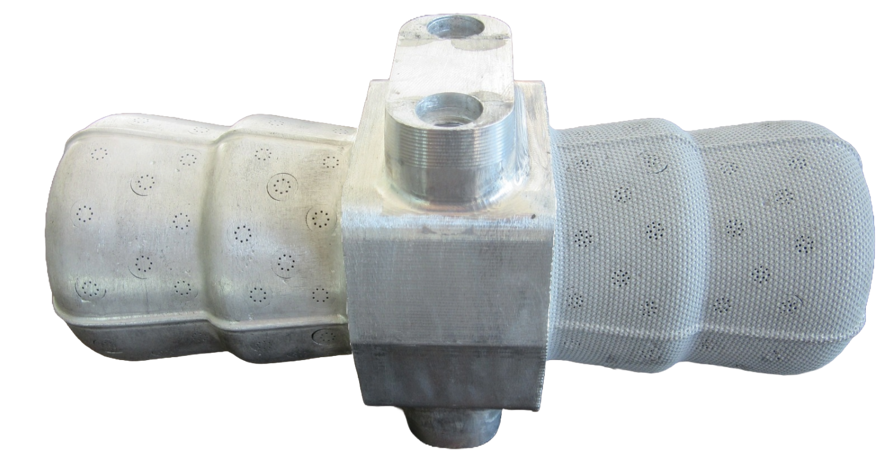

You can prepare your molds and make ventilation holes and then send them to us for engraving: the laser beam works the surface without damaging the holes.

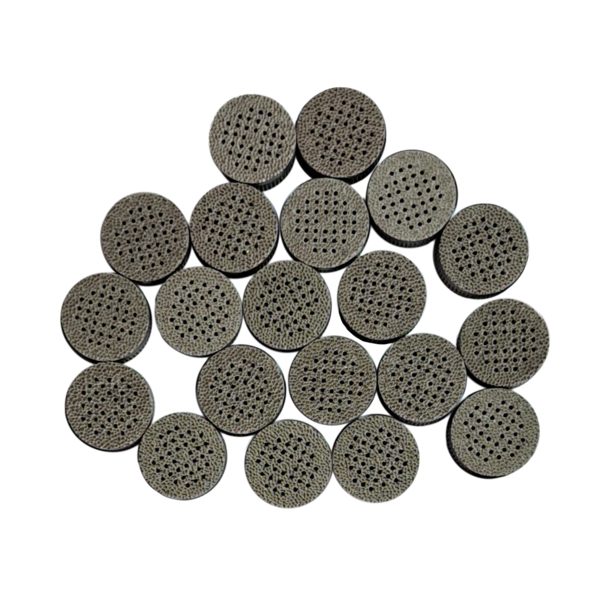

We also work in series your rods to always have the necessary stock available to complete the stamping cycles.

With our 22 laser machines, we quickly manage even very large orders with numerous moulds.